效率创新高

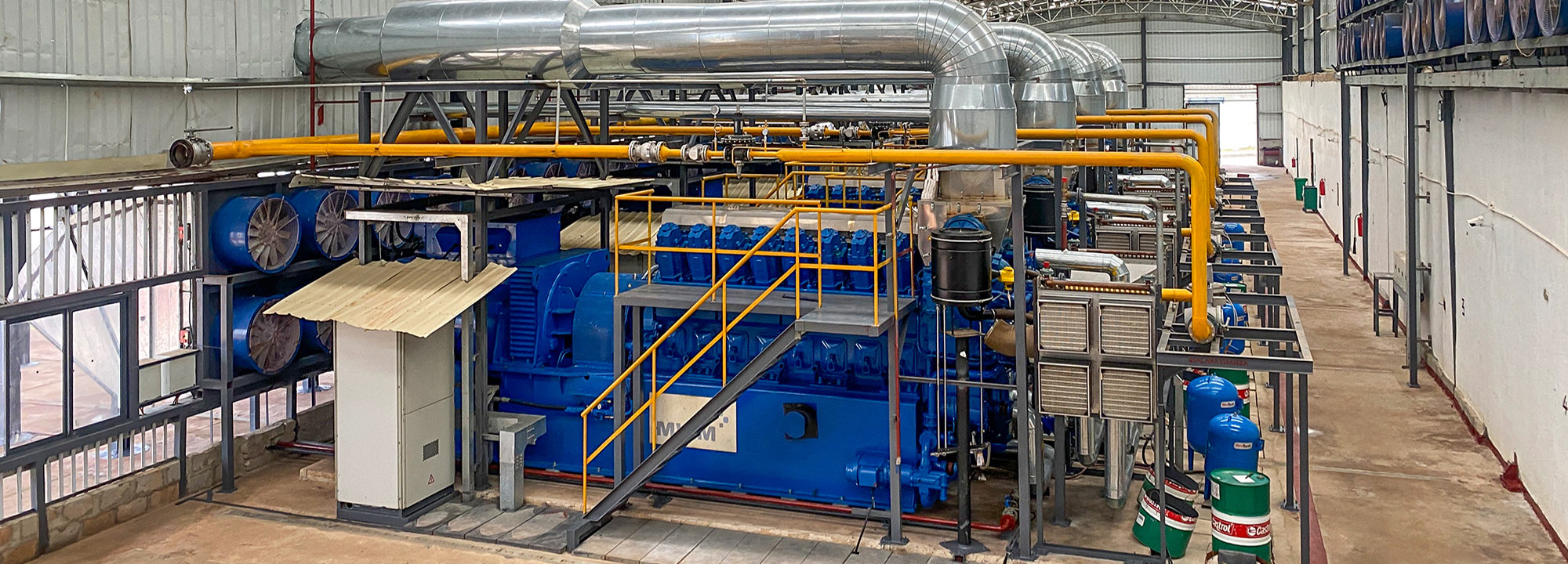

天燃气和生物沼气应用时单机输出功率在3.300-4.500 KW ei 之间

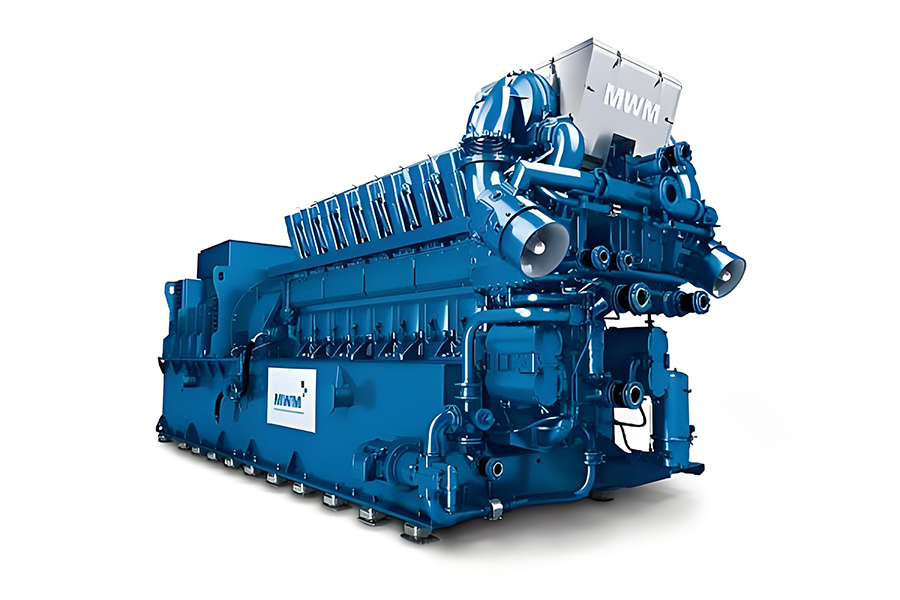

TCG 2032 / 功率3000-4500KW

产品特性

更高的收益

气缸模块化使维护更便捷,减少拆卸不同部件的数量,可更大限度的缩短维护时间,这样可以节省高达20%的服务费用。同时,与同类型的发电机组相比可节省高达30%的润滑油消耗,从而使您获得更高的收益。

更长的运行时间

与同类型的发电机组相比,保养周期的延长使TCG2032机组每年运行时间可延长高达200小时且机组大修时间可延长到80000小时。

更高的可靠性

采用预燃室火花塞的无颗粒排放技术,与其他燃烧方式相比,延长了烟气余热交换器的维护周期,降低了维护成本。活塞,连杆,火花塞和缸头等主要部件都进行了改进,以便增大输出功率并获得更高的电效率。

更佳的能效

所有相关部件都得到了进一步的改善,TEM(全电子管理)控制系统监控所有与效率和输出功率相关的部件,尤其是更新升级后的废气旁通阀可在背压不断变化的条件下确保机组更高效的运转。TEM控制系统对每个气缸都进行着温度检测,当气体成分有波动时,可以做出快速反应。TEM控制系统不仅控制发动机,而且能够控制包括余热利用在内的整个系统。

满功率输出

A140涡轮增压器结合升级后的废气旁通阀支持机组在更广泛的进气温度范围内和海拔条件下满功率输出。

TCG 2032 50 Hz 技术数据

| 发动机型号 |

|

V12 | V16 | B V16 |

|

缸径/冲程 |

mm |

260/320 |

260/320 | 260/320 |

| 排气量 | dm3 |

203.9 |

271.8 | 271.8 |

| 转速 | min-1 | 1,000 | 1,000 | 1,000 |

| 平均活塞速度 | m/s |

10.7 |

10.7 | 10.7 |

| 长度 | mm |

7,860 |

9,271 | 9,272 |

| 宽度 | mm | 2,660 | 2,790 | 2,790 |

| 高度 | mm |

3,390 |

3,390 | 3,390 |

| 发电机组净重 | kg |

43,100 |

51,200 | 51,400 |

| 天燃气应用 | NOx ≤ 500 mg/Nm3 | |||

| 电功率 | kW |

3,333 |

4,300 | 4,500 |

| 平均有效压力 | bar |

20.0 |

19.4 | 20.3 |

| 热输出 |

kW |

3,238 |

4,164 | 4,259 |

| 电效率 | % |

43.9 |

44.1 | 44.1 |

| 热效率 | % |

42.6 |

42.7 | 43.2 |

| 总效率 | % |

86.5 |

86.8 | 87.8 |

| 沼气应用 |

NOx ≤ 500 mg/Nm3 最低热值 (LHV)Hu = 5,0kWh/Nm3 污水处理沼气 [65%CH4 / 35%CO2] 生物沼气 [60%CH4 / 32%CO2 / 其余为N2] 垃圾填埋沼气 [50%CH4 / 27%CO2 / 其余为N2] |

|||

| 电功率 | kW |

|

3,770 |

|

| 平均有效压力 | bar |

|

17.0 |

|

| 热输出 | kW |

|

3,496 |

|

| 电效率 | % |

|

43.0 |

|

| 热效率 | % |

|

39.8 |

|

| 总效率 | % |

|

82.8 |

|

TCG 2032 60 Hz 技术数据

| 发动机型号 |

|

V12 | V16 | B V16 |

|

缸径/冲程 |

mm |

260/320 |

260/320 | 260/320 |

| 排气量 | dm3 |

203.9 |

271.8 | 271.8 |

| 转速 | min-1 |

900 |

900 | 900 |

| 平均活塞速度 | m/s |

9.6 |

9.6 | 9.6 |

| 长度 | mm |

8,000 |

9,420 | 9,420 |

| 宽度 | mm |

2,790 |

2,790 | 2,790 |

| 高度 | mm |

3,390 |

3,390 | 3,390 |

| 发电机组净重 | kg |

40,650 |

52,400 | 52,400 |

| 天燃气应用 | NOx ≤ 500 mg/Nm3 | |||

| 电功率 | kW |

3,000 |

4,000 | 4,050 |

| 平均有效压力 | bar |

20.1 |

20.2 | 20.4 |

| 热输出 |

kW |

2,877 |

3,866 | 3,891 |

| 电效率 | % |

43.9 |

43.9 | 44.3 |

| 热效率 | % |

42.1 |

42.4 | 42.6 |

| 总效率 | % |

86.0 |

86.2 | 86.9 |

| 沼气应用 |

NOx ≤ 500 mg/Nm3 最低热值 (LHV)Hu = 5,0kWh/Nm3 污水处理沼气 [65%CH4 / 35%CO2] 生物沼气 [60%CH4 / 32%CO2 / 其余为N2] 垃圾填埋沼气 [50%CH4 / 27%CO2 / 其余为N2] |

|||

| 电功率 | kW |

|

3,510 |

|

| 平均有效压力 | bar |

|

17.0 |

|

| 热输出 | kW |

|

3,125 |

|

| 电效率 | % |

|

43.3 |

|

| 热效率 | % |

|

38.5 |

|

| 总效率 | % |

|

81.8 |

|